Why Choosing the Right Pulley System is Important

Selecting the perfect Pulley System is crucial for optimizing the efficiency and safety of engineering projects. The right pulley system can save time, reduce costs, and improve overall project performance.

Understanding the factors that influence this decision can lead to better outcomes.

Key Factors to Consider When Choosing a Pulley System

- Load Capacity

Ensure the pulley system can handle the maximum load your project requires. Always account for the weight of the load and include a safety margin. - Type of Pulley

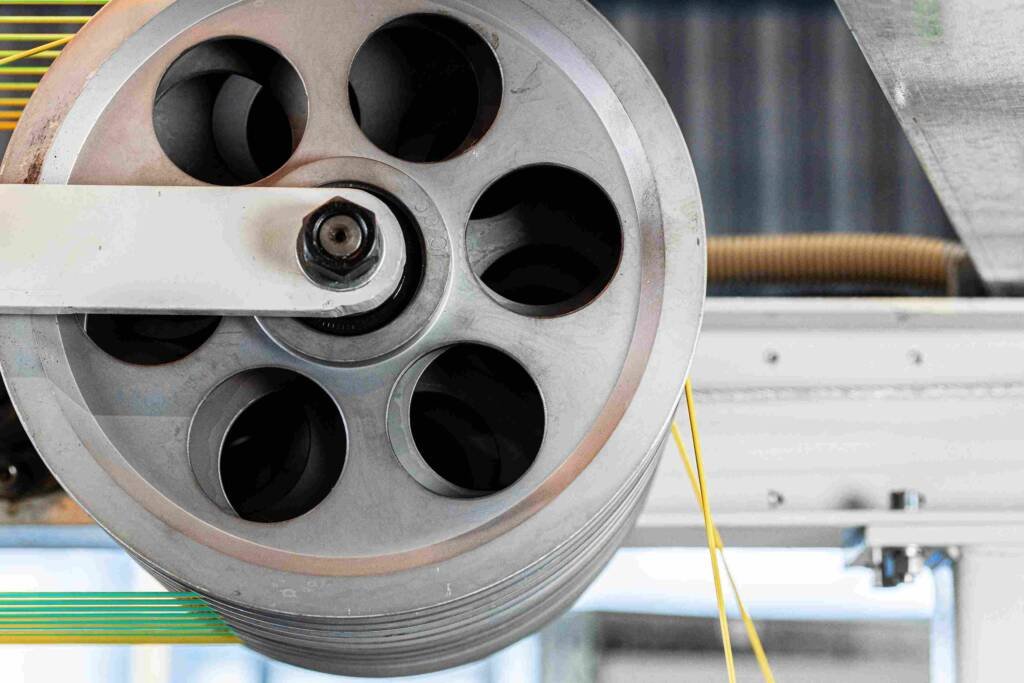

Depending on the project, you may need fixed, movable, or compound pulleys. Each type offers specific advantages, such as mechanical advantage or ease of use. - Material and Durability

The material of the pulley (steel, aluminum, plastic) should match the environment of the project. Consider factors like corrosion resistance and longevity. - Speed and Efficiency

Consider the speed at which the pulley system will operate. Some projects require high-speed movement, while others benefit from slower, more controlled operation. - Space and Setup Constraints

Evaluate the available space for the pulley system and ensure it fits within the layout of your project. Compact setups might be necessary for limited spaces.

Different Pulley Systems and Their Applications

- Single Pulley Systems

Best for small, lightweight loads, providing basic mechanical advantage. - Compound Pulley Systems

Suitable for heavy-duty tasks, providing a significant mechanical advantage and reducing the required force. - Electric and Automated Pulley Systems

Used in large-scale projects or where automation and precision are required, often seen in manufacturing and construction.

How to Match the Pulley System to Your Engineering Needs

To match the pulley system to your needs, calculate the required mechanical advantage and load capacity. Factor in the environment in which the system will operate, as this will influence material and durability requirements.

Also, consider the complexity of your project, as more intricate designs may require more advanced systems.

Conclusion:

Choosing the perfect Pulley System is essential for the success of your engineering projects. By considering factors like load capacity, pulley type, material, and space requirements, you can ensure optimal performance. For expert guidance on pulley systems, AH Engineering Works.

FAQ’s:

- What is the most important factor when choosing a pulley system?

The load capacity is the most important factor, ensuring the pulley can safely handle the weight.

- How do I know which type of pulley system to choose?

Choose based on the load size and the mechanical advantage required for your project.

- What materials are best for pulley systems?

Steel and aluminum are ideal for strength, while plastic is used in lighter, less demanding applications.

- Can pulley systems be automated?

Yes, electric and automated pulley systems are available for high-precision tasks.

- How do I calculate the correct pulley system for my project?

Calculate the load, mechanical advantage needed, and available space to determine the right system.